Manufacturing Process

Manufacturing Process  Manufacturing Process

Manufacturing Process

The manufacturing process of Transmission Bearings begins with the selection of high-quality raw materials. This ensures the durability and performance of the final product.

The raw materials are then precision-cut into the specific shapes required for the bearings. This process is carried out using advanced machinery to ensure accuracy and consistency.

Next, the cut pieces undergo heat treatment. This process strengthens the material and enhances its resistance to wear and tear, ensuring the longevity of the bearings.

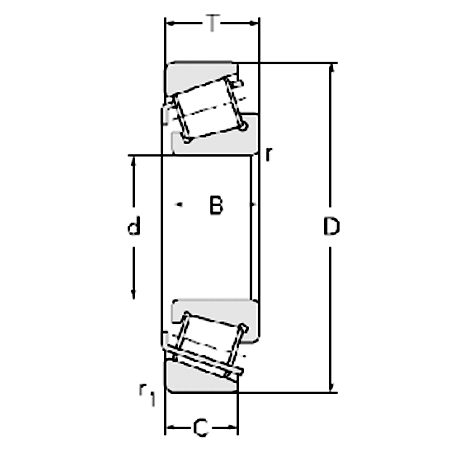

Finally, this kind of tapered roller bearings are assembled and thoroughly tested for quality. This includes checks for dimensional accuracy, smoothness of operation, and overall performance. Only after passing these rigorous tests are the Transmission Bearings deemed ready for use.

Diagram

Diagram